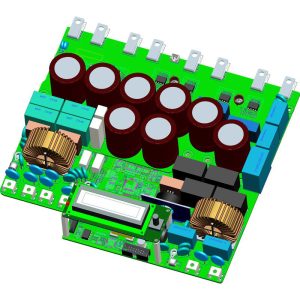

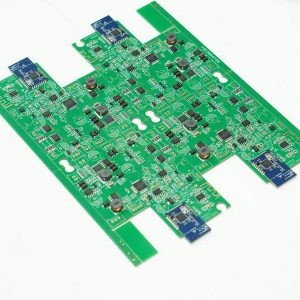

PCB Assembly

Surface-Mount Technology

Surface-mount technology (SMT) is an assembly process that involves mounting electronic components to the surface of a PCB. It is highly automated and flexible, and it allows for higher connection densities. It enables manufacturers to place complex circuitries into small components.

The four basic steps of PCBA SMT are:

Preparing the PCB: First, the assembler places solder paste where it is needed on board.

Placing the Components: Next, the assembler places the components on the board, typically using a pick-and-place machine.

Reflow Soldering: The assembler then heats the boards in a reflow oven until the solder paste reaches the temperature required for the solder joints to form.

Inspection: The assembler conducts inspections throughout the SMT process, including before attaching the components and before and after reflow soldering.

Thru-Hole Technology

Thru-hole technology is an assembly process that involves drilling holes into a PCB through which electronic components called leads can be attached. It is an older technology than SMT but creates a stronger connection between the board and the components, which makes for more durable and reliable assemblies.

Thru-hole assembly can be either fully automated or semi-automated. The steps of the PCBA thru-hole process include:

Drilling the Holes: The first step in the thru-hole process involves drilling holes into the board. These holes must be the right size for the component leads.

Placing the Leads: Next, the assembler places the leads in the holes.

Soldering: The next step in the process is soldering. This step ensures the components are held firmly in place.

Inspection: Throughout the process, the assembly undergoes inspections to ensure the PCBA will function as expected.

Shenzhen Thriver Digital Tech Co., Ltd – Best Choice for PCB Assembly Suppliers

During the process of PCB Assembly and PCB manufacturing, our company adopts a series of systematic methods to ensure that each link can achieve high standards of quality and efficiency.If you looking for a PCB Assembly Suppliers, please send your BOM file and PCB files to sale@OEM-PCBA.COM . All your files are highly confidential. We will send you an accurate quote with lead time in 24 hours.

Our Company Since 2012.One Stop Service PCB Manufacturer, PCB Design,PCB Copy,PCB Layout,PCB Manufacturer,BOM Kitting,PCB Assembly,OEM PCBA,ODM PCBA Function test,etc. Professional One-Stop Turnkey Service for PCB Circuit Board Factory.Professional PCB Assembly suppliers for 10 Years of Electronic components Distribution list and PCB assembly industry experience.Contact Us Today

Showing all 13 results

-

12V 24V Dc To 220V Solar Power Inverter PCB Board

Read more -

12V Dc To 220V Solar Hybrid Power Factory Original Oem Iot Inverter Electronic PCB Circuit Board

Read more -

China pcba for led light aluminium based pcb for leds

Read more -

Dust Collector PCBA manufacturer PCB Assembly Serviece

Read more -

Home appliance pcba custom pcb board supplier

Read more -

Led circuit board manufacturing aluminium substrate pcba

Read more -

Led lighting pcb assembly Aluminium pcb for led

Read more -

OEM Electronic Fire Alarm Control Panel PCBA Circuit Board

Read more -

OEM/ODM Fire Alarm System Control Panel PCB Board

Read more -

Pcba professional manufacturer Medical Equipment Pcba Board

Read more -

Pressure Sensor Medical Electronic Care Device PCB Board Assembly

Read more -

Printed circuit board assembly massager control pcba board manufacturers

Read more -

Professional Custom PCB and PCBA manufacturer pcba circuit board Board Assembly

Read more