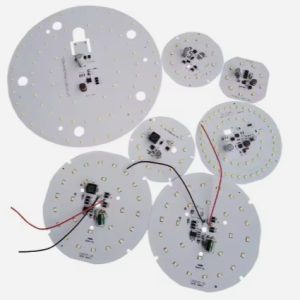

LED Aluminium PCBA

What is Aluminum PCB?

An aluminum PCB has a similar layout to any other PCB. It has a layer or layers of copper, solder mask and silkscreen layered over it. Instead of having a fiberglass or plastic substrate, though, an aluminum circuit board has a metal substrate. This base mainly contains a combination of aluminum. The metal core can consist entirely of metal or have a combination of fiberglass and aluminum. Aluminum PCBs typically are single sided, but can be double sided as well. Mulilayer Aluminum PCBs are highly difficult to manufacture. Aluminum boards are one of the most thermally conductive PCB options. Aluminum boards get the most use in LED and power converting electronics. They keep as much heat away from vital components as possible to ensure minimal circuit damage.

Different Types of Aluminum PCBs

Flexible Aluminum PCBs: These use new flexible dielectrics featuring Polyimide resin systems with ceramic fillers for excellent electrical insulation, thermal conductivity, and flexibility. The metal base uses flexible Aluminum such as 5754 or similar. The combination produces a PCB that the user can bend into place, but not use for regular flexing.

Hybrid Aluminum PCBs: These use a non-thermal material as the sub-assembly, which the fabricator processes independently, and then bonds to the Aluminum base using thermal materials. For instance, a conventional 2- or 4-layer FR-4 PCB bonded to an Aluminum base helps to improve heat dissipation and mechanical rigidity.

Multi-Layer Aluminum PCBs: Fabricators make these from multiple layers of thermally conductive dielectrics. The designer can place one or more layers of circuits buried in the dielectrics, and use blind and buried vias. However, these PCBs are not so effective in transferring heat.

Through-Hole Aluminum PCBs: Prior to lamination, the fabricator must pre-drill the Aluminum base, and back-fill it with dielectric to form the core of a multi-layer PCB. This allows the fabricator to laminate both sides of the Aluminum base with thermal materials and PCB subassemblies. After lamination, the fabricator can drill the assembly like drilling a conventional multilayer PCB, with plated through holes passing through the clearances in the Aluminum. This is the most complex construction of an Aluminum PCB.

Aluminum PCB Performance

Thermal Dissipation

Compared with ordinary FR4 PCBs, aluminum PCBs perform better in terms of thermal dissipation and they are capable of dissipating heat quickly. Take comparison between FR4 PCB and aluminum PCB with equivalent thickness of 1.5mm as an example. Thermal resistance of FR4 PCB is from 20°C/W to 22°C/W while that of aluminum PCB is from 1°C/W to 2°C/W. Thus, aluminum can work well on thermal dissipation.

Thermal Expansion

Thermal expansion and contraction is the common nature of substances and different substances carry different coefficients of thermal expansion. Now that aluminum PCBs perform excellently in terms of thermal dissipation, thermal expansion and contraction issues of components on board surface can be therefore dramatically reduced with durability and reliability of complete appliance and electronic equipment. This merit of aluminum PCBs especially works smoothly for thermal expansion and contraction issues of SMT (surface mount technology).

Dimensional Stability

Aluminum-based PCBs feature obviously stable size. When they are heated from 30°C to 140°C or 150°C, their size changes by only 2.5% to 3.0%.

Other Performances

Applicable for power device SMT.

Effective in thermal expansion of circuit design.

Helpful in reducing operating temperature, improving product power density and reliability and prolonging product’s shelf life.

Shrinking product’s volume and decreasing hardware and assembly cost.

Replacing fragile ceramic base, with better insulating property and mechanical endurance.

Shenzhen Thriver Digital Tech Co., Ltd – Best Choice for PCB Electronic Board Assembly

During the process of PCB design and PCB manufacturing, our company adopts a series of systematic methods to ensure that each link can achieve high standards of quality and efficiency.

Our Company Since 2012.One Stop Service PCB Manufacturer, PCB Design,PCB Copy,PCB Layout,PCB Manufacturer,BOM Kitting,PCB Assembly,OEM PCBA,ODM PCBA Function test,etc. Professional One-Stop Turnkey Service for PCB Circuit Board Factory.Professional PCB Assembly suppliers for 10 Years of Electronic components Distribution list and PCB assembly industry experience.Contact Us Today

Showing all 9 results

-

Aluminium core pcb assembly led pcba solutions

Read more -

China pcba for led light aluminium based pcb for leds

Read more -

Custom Aluminium PCB Board , LED PCB board

Read more -

Custom led aluminium pcb board led light pcba design

Read more -

Custom-made Aluminum LED Pcb Circuit Board Lighting Pcb Pcba Design Manufacturer

Read more -

Led circuit board manufacturing aluminium substrate pcba

Read more -

Led lighting pcb assembly Aluminium pcb for led

Read more -

led pcb aluminium board LED pcb assembly

Read more -

Led pcb aluminium board led light pcb design

Read more