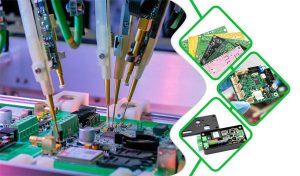

PCB Assembly Process Explained:

PCB (Printed Circuit Board) assembly is a crucial part of the electronics manufacturing field, it will be electronic components precisely installed on the circuit board to ensure that the circuit board can work properly according to the design requirements. This article will detail the various steps and techniques of PCB assembly to help readers fully understand this complex and sophisticated process.

Basic concepts of PCB assembly

Composition of PCB

PCB is mainly composed of the following parts:

Substrate: usually made of FR-4 material, providing mechanical support for the circuit board.

Copper layer: Used to form the conductive path of the circuit.

Solder pads: Used to connect the pins of the components to the copper layer on the circuit board.

Solder Paste: Used to hold components in place and form electrical connections.

Solder Paste Mask: prevents solder paste from spreading in non-soldered areas.

Silk Screen Layer: Used to mark the name and orientation of components.

Purpose of PCB Assembly

The purpose of PCB assembly is to accurately install electronic components on the circuit board to form a complete circuit system and to ensure that the circuit board can work properly according to the design requirements.

The main steps of PCB assembly

- Design and preparation

Before starting the assembly, detailed design and preparation work is required. This includes:

Designing circuit diagrams: CAD software is used to design circuit diagrams and layouts.

Generate Gerber files: These files contain all the design information for the board and are used to guide production.

Material Selection: Selection of suitable substrate materials and electronic components.

- Solder Paste Printing

Solder paste is a mixture of solder and flux used to secure components and form electrical connections.

Printing of solder paste: Use stencils or screens to accurately print the paste onto the circuit board.

Inspection: Ensure the printing quality of the solder paste to avoid leakage or overprinting.

- Component Placement

Component placement is a critical step in PCB assembly and requires a high degree of precision and accuracy.

Automatic placement: Use the automatic placement machine to place the components on the solder paste.

Manual placement: For some special components, manual placement may be required.

- Reflow Soldering

Reflow soldering is the process of heating the solder paste to a liquid state so that the components are held on the board and an electrical connection is formed.

Preheat: The board is preheated to a temperature where the solder paste begins to soften.

Reflow: The board is passed through a reflow oven where the solder paste completely melts and solidifies.

Cooling: Cool the board to room temperature to ensure solid soldering.

- Inspection and Testing

After the assembly is completed, rigorous inspection and testing is required to ensure that the circuit board can work properly.

Visual inspection: Check whether the components are correctly placed and whether the solder joints are even.

Function Test: Test the function of the board to ensure that all components work properly.

- Final Assembly

After inspection and testing are passed, the circuit board is ready for final assembly, including mounting the case, connecting the power supply, and so on.

Technical Challenges and Solutions

- Component placement accuracy

The accuracy of component placement directly affects the performance of the board. Modern assembly technology uses high-precision automatic placement machines that are capable of achieving micron-level accuracy.

- Soldering Quality

Soldering quality is the key to PCB assembly. Modern soldering technology uses reflow soldering, which can realize high quality soldering.

- Quality control

Quality control is an important part of PCB assembly. Modern assembly technology uses a variety of quality control means to ensure that the circuit board can meet the design requirements.

Conclusion

PCB assembly is a complex and sophisticated process that requires a high degree of technical support and quality control. Through the introduction of this paper, readers can fully understand the various steps and techniques of PCB assembly for better design and manufacturing of electronic products.

Rchangltd a one-stop solution for PCB manufacturing services with specialized support, reliable testing, and multi-functional features. In case if you have any questions, please feel free to contact us via email at sale@OEM-PCBA.COM